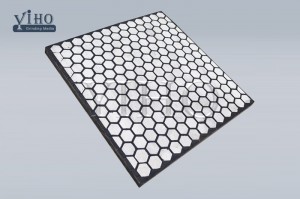

Nganggo tahan baja-karet-keramik panel vulcanized piring keramik

Katrangan rinci

Ing aplikasi industri agresif, peralatan ngendi impact dhuwur, abrasion dhuwur mesthi nandhang serangan mechanical, serangan kimia, karat, utawa dening kombinasi saka telung mode iki.

Keramik YIHO bisa nawakake macem-macem piring liner keramik kanggo lingkungan abrading pelanggan.Lapisan nyandhang keramik komposit ditrapake kanggo aplikasi sing paling angel kanthi bahan sing dhuwur banget.nalika kombinasi nyandhang nemen lan resistance impact lan urip nyandhang dawa dibutuhake, Ultraming nawakake liner nyandhang keramik gabungan karo bata Keramik gedhe lan hard vulcanized menyang matriks saka karet tahan nyandhang .amarga sifat lentur sawijining tumindak karet minangka dampener a.Iku ndadekake iku bisa kanggo nggunakake prodhuk iki ing aplikasi karo akèh impact tanpa resiko crushing bata Keramik.

Fitur produk

> atose dhuwur

> Superior abrasion lan impact resistance

> Karat lan resistance kimia

> bobot entheng

> Gampang instalasi dening resin epoxy utawa bolt

> Ningkatake lingkungan kerja - swara, geter lan safety

Kothak keramik alumina kanggo vulkanisasi kalebu

- kothak kothak: 10x10x2~10mm, 17.5x17.5x2~15mm, 20x20x2~15mm, 33x33x7~25mm, etc.

- Piring Keramik: 100x100x6~50mm, 150x100x6~50mm, lsp.

- Kothak heksagonal: S12xT3~20mm, S19xT6-25mm

- Blok Keramik: 40x40x40mm, 32x32x22mm, 38x38x38mm, lsp.

- Keramik Silinder / rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 50x50mm etc.

Keuntungan utama komposit karet keramik

- Resitance nyandhang banget

- Anti-impact banget amarga sifat elastis saka karet

- Gampang instalasi banjur nyuda downtime

- Ngurangi polusi jiwa.

Aplikasi saka peralatan

- Tong sampah

- Feeders

- Chutes

- Bunker

- Panyimpenan

| S. Ora. | Bahan | Atribut | Properti |

| 1 | Kothak Keramik | Bahan | 92%, 95%, T95%, 96%, ZTA |

| 2 | karet | Komponen | karet alam, karet nitrile-butadiena, Flame Retardant, liyane |

| Kapadhetan | ~1,4 g/cm3 | ||

| Kekuwatan tensile ing break | ≥15Mpa | ||

| Elongation ing break | ≥250% | ||

| Hardness Shore | 45-65 | ||

| Adhesive antarane kothak lan karet | 1.2-3.0 Mpa | ||

| Adhesive antarane karet lan peralatan | ≥3,5 Mpa | ||

| Konduktivitas termal (suhu normal) | 2 w/m·k | ||

| Periode tuwa | ≥15 Taun | ||

| Suhu kerja | -50ºC - 200ºC | ||

| 3 | Plat baja | Bahan | Q235A |

| Kapadhetan | 7,85 g/cm3 | ||

| kekandelan | 5-6 mm | ||

| 4 | Adhesive | Penampilan | Cairan ketan coklat |

| Isi padhet | 20±3% | ||

| Viskositas | ≥2,5 Mpa | ||

| Kekuwatan kulit | 48 jam N/2,5cm≥120 | ||

| Kekuwatan kompresif | ≥850 Mpa | ||

| Suhu kerja | -20ºC - 100ºC |

| Kabeh piring (mm) | 150x300, 300x300, 450x000, 500x500, 600x450 lsp. |

| Ukuran Keramik (mm) | Kothak kothak: 10x10, 20x20, 33x33, 50x50, 100x100, 150x100, lsp. |

| Kothak Heksagonal: 12x3, 12x6, 19x7, 19x12.5, 19x25, lsp. | |

| Blok ngunci kanthi kunci lan alur: 38x38, 40x40, 30x30, lsp. | |

| Ubin Lesung: 20x20 karo 5 lesung, 20x30 karo 18 lesung, 20x30 karo 13 lesung, 20x20 kanthi 1 lumahing semi-bunder | |

| Ketebalan Keramik (mm) | 3-75 mm |

| Ukuran Baja Paduan (mm) | Ketebalan: 3-10 mm |

| Ketebalan karet (mm) | Gumantung ing kaku impact samesthine. |