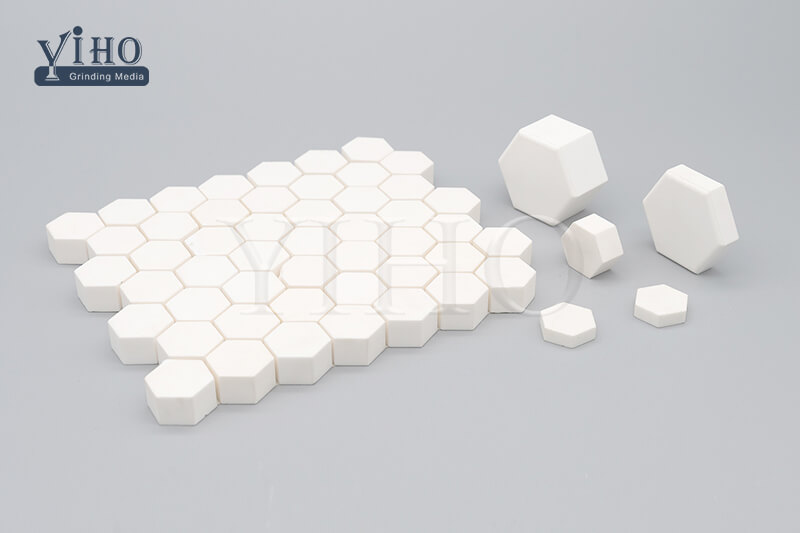

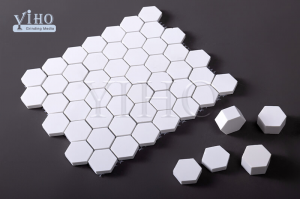

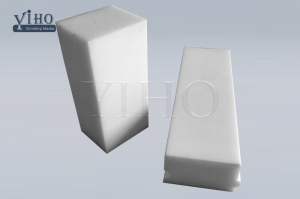

Wear lan Impact Conveyor Chute Wear Liner Alumina Keramik Rubber Wear Plate

Katrangan

Conveyor Chute Wear Resistant Ceramic Rubber Liner digawe saka keramik alumina dhuwur lan karet alam berkualitas tinggi sing ditambah karo proses khusus.Sifat panyerepan kejut sing apik banget saka karet alam mbantu entuk resistensi impact tartamtu, saéngga nyegah ubin saka retak ing area impact dhuwur, sing nduweni efek sing luwih unggul dibandhingake karo ubin lapisan keramik sing langsung diikat menyang pabrik baja.Dibandhingake karo baja tahan nyandhang, karakteristik Conveyor Chute Wear Resistant Ceramic Rubber Liner nggawe luwih tahan kanggo nyandhang lan impact.Urip layanan luwih suwe tinimbang produk lapisan tahan nyandhang sadurunge, lan bisa tahan kanggo pirang-pirang siklus mati tanpa nyebabake nyandhang utawa gagal serius.

Sifat Kimia

| S. Ora. | Bahan | Atribut | Properti |

| 1 | Kothak Keramik | Bahan | 92%, 95%, T95%, 99%, ZTA, RBSIC |

| 2 | karet | Komponen | karet alam, karet nitrile-butadiena, Flame Retardant, liyane |

| Kapadhetan | ~1,4 g/cm3 | ||

| Kekuwatan tensile ing break | ≥15Mpa | ||

| Elongation ing break | ≥250% | ||

| Hardness Shore | 45-65 | ||

| Adhesive antarane kothak lan karet | 1.2-3.0 Mpa | ||

| Adhesive antarane karet lan peralatan | ≥3.8 Mpa | ||

| Konduktivitas termal (suhu normal) | 2 w/m·k | ||

| Periode tuwa | ≥15 Taun | ||

| Suhu kerja | -50ºC - 200ºC | ||

| 3 | Plat baja | Bahan | Q235A |

| Kapadhetan | 7,85 g/cm3 | ||

| kekandelan | 5-6 mm | ||

| 4 | Adhesive | Penampilan | Cairan ketan coklat |

| Isi padhet | 20±3% | ||

| Viskositas | ≥2,5 Mpa | ||

| Kekuwatan kulit | 48 jam N/2,5cm≥120 | ||

| Kekuwatan kompresif | ≥850 Mpa | ||

| Suhu kerja | -20ºC - 100ºC |

Aplikasi Conveyor Chute Wear Resistant Keramik Rubber Liner

Conveyor Chute Wear Resistant Ceramic Rubber Liner nyedhiyakake lapisan tahan nyandhang kanggo macem-macem peralatan, chutes, pipa, hopper, tong sampah, siklon, lapisan peralatan screening lan industri liyane.